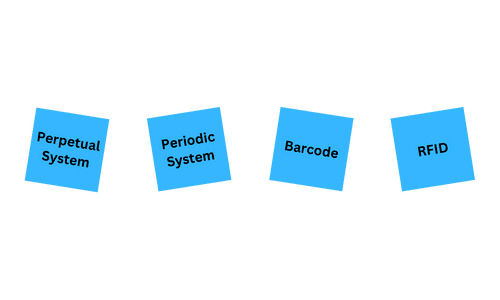

- Perpetual System

- Periodic System

- Barcode System

- Radio frequency Identification System (RFID)

Topics in this Article

By Definition: Inventory Management

Inventory Management – 4 Methodologies

Merging Inventory Management with Inventory Control

How Effective Inventory Management Benefits Your Business

Demand Planning

Techniques to Make Your Inventory Management System More Effective

Gain Control Over Your Inventory Management Processes

By Definition : Inventory Management

Good practice allows for efficiency in tracking orders and purchases, effectively monitoring processes and meeting delivery requirements within the supply chain.

The choice of system to provide your company the ability to realise optimal performance is not a simple one. Some companies choose a manual process, and others rely on software programmes to keep control over their records and procedures

Inventory Management - 4 methodologies

Every organisation has a unique set of inventory requirements to support operational production. The four kinds of management systems that provide you the necessary methodologies to achieve balance come with their associated pros and cons, risks and specific applications. They’re all sound in principle and effective when implemented properly to frame your needs.

- Perpetual System

Favoured by businesses, stakeholders and retailers, the Perpetual system allows for the implementation of a continual inventory process. The procedure calls for immediacy, and movement is recorded in real-time.

Up-to-the-minute reporting provides metrics and analytics on your flows and highlights issues that may arise in the immediate environment. The Perpetual System is a long-term solution to gaining valuable insights and serves as a great marker for the Executive to set new goals and respond to changes in the business landscape.

The system makes use of a POS(Point-Of-Sales) that calculates inventory and storage information without relying on a manual process.

While extremely effective, this system does require an initial set-up fee and involves a training component. Staff will have to be taught how to use the system properly. Errors that occur where untrained or semi-trained staff fail to manage the system effectively costs time, money and resources.

- Periodic System

The Periodic system tracks your inventory at specific intervals that adhere to accounting processes. Though the Periodic System follows a pattern and slots in where a counting process is requisite, it can prove effective where smaller inventories demand less input.

Because the procedure is based on manual tabulation, caution needs to be exercised regarding time constraints. Human error cannot be overlooked where counting processes need to provide accurate results. Costs are kept low with this system and the staff complement needed to execute the process tends to remain specific.

This system works at its best at the implementation stage where minimal input is required in the set-up phase. No technology is used to facilitate a structured manual procedure. In the case of small businesses, the result is determined by due diligence and regularity.

- Barcode System

As the name suggests, the Barcode System tabulates inventory through the use of barcodes. It’s a virtual system favoured by organisations in order to categorise an inventory on a “needed, scanned and used” model. The system provides updated information on stock levels, manufacturing phases and procedures, packing, and shipping schedules. The barcode system serves a multi-faceted production requirement where production costs and streamlined processes are crucial to successful inventory management.

The barcode system keeps your processes synchronised and allows for in-depth planning around the supply chain. The system is considered low risk because there’s little room for human error.

Customisation capabilities makes the Barcode System particularly attractive to companies with extensive product lifecycle portfolios and large inventory requirements, or a distributed geo-logistic footprint. This allows for customisation by isolating specifics, for example, project-type, product cluster, demand, and location, to name a few markers.

Barcoding, by nature, is time-consuming, from assignation to generation, and lastly, application. However, the benefits gained from barcode software far outdoes the tedium associated with the process. It is possible to couple machine learning to barcode software in order to generate virtual barcodes, and organise them as required.

- Radiofrequency Identification System (RFID)

The Radiofrequency Identification technique makes use of tags. Each tag is attached to a variety of items that generate radio signals containing product information. The RFID system works similarly to the barcoding system. It, too, facilitates virtual tracking.

Because RFID tags do not require scanning, this system is preferred to barcoding. Tracing the inventory, especially in transit, becomes easier because the process is not location dependent. The probability for human error lessens significantly, as do labour costs and the amount of time required to perform tasks with the RFID system.

The expenditure associated with implementing an RFID system is high. Installation and the training required to successfully automate and optimise a company’s inventory processes can become expensive, added to which are security concerns where data repositories require access control. Securing an inventory poses a challenge due to the design of radiofrequency modelling.

Merging Inventory Management with Inventory Control

Inventory management and inventory control work together as an effective combination to gain control over efficiencies and deficits.

The immediate environment requires continuous assessment and accurate information. How does each process compliment the other?

Inventory Management

- Complete overview of the entire inventory holding

- Provides a yardstick for items in-stock and items that require replenishing

- Allows for an accurate representation of inventory in the immediate environment

- Suggested requirement - automation software

- Supports supply chain management and warehousing inventory procedures

Inventory Control

- Used as a tool to regulate stock holding

- Ensures efficiency in the regulation of the immediate environment

- Internal optimisation – inventory control is put into place before automation of the management process

How Effective Inventory Management benefits your business

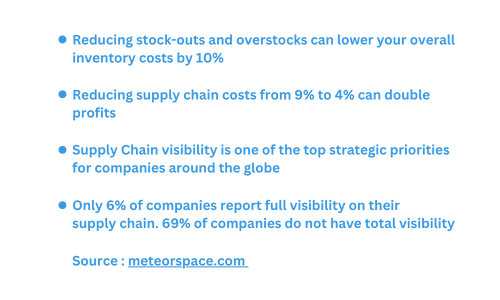

An optimised inventory management strategy provides you total control and authority over your systems, and ultimately, your business or organisation. If you consider that only 6% percent of businesses have complete visibility on their supply chain, and the drive to make improvements has become a priority for companies around the globe, gaining clarity should represent a crucial business objective.

Let’s delve into why improving functionality and process provides the ability to realise growth and cut losses:

Increased Profitability

Delivering on your objectives, both internal and external, places you in a position to improve cash flow and generate profit. Optimal inventory management provides you the tools to make improvements. Monitoring your inventory gives you an accurate measurement of the stock you have available and informs your demand planning initiatives in order to plan, prepare and process inventory turnover.

Accuracy

Human error accounts for the majority of inventory distortions experienced by the vast majority of businesses. Continuous monitoring creates an environment that supports optimisation, precision and accurate demand planning. Eliminating human and technological error saves time, aids workflows and solidifies procedures.

Improved Customer Relationships

Stock deficits contribute to the loss of a valuable customer base. Loyalty is dependent on product availability, first and foremost. Purchasers are not likely to wait for stock to be replenished, or readily accept being advised that an item is out of stock after a purchase has been finalised.

In order to retain customer loyalty and avoid losing a sale to a competitor, availability and proper allocation determines success in the short and long-term. Reliability builds trust. In today’s market, customers place a high precedent on exemplary service. Good inventory management is the core function that facilitates a healthy relationship with your customer.

Risk Management

One of the main advantages of implementing an effective inventory management strategy is balancing shortage and surplus. Buying stock at the right pace and at the correct intervals meets the requirements that dictate supply and demand and helps you avoid over-purchasing slow movers, or running out of popular stock items.

Time Management

A good inventory management system allows your processes to flow seamlessly. It helps you avoid confusion, searching for stock and cleaning up messy misunderstandings that negatively influence your relationship with your customers. No matter which system you opt to use, organising your inventory brings you a step closer to realising your business objectives.

Demand Planning

An integral part of Supply Chain Management (SCM), demand planning helps you predict customer needs in the future, and gives you the knowledge to plan accordingly. It’s way of predicting supply and demand.

The ideal situation prepares ahead of time. This means that the company procures stock that satisfies demand when it arises. A variety of factors influence the business landscape and often, trends and needs are difficult to predict with precision.

Efficiency is the key. There is little benefit to carrying stock that meets neither demand nor expectation. The flip side is lamenting missed opportunity, where demand cannot be met due to lack of inventory.

An accurate demand planning forecast helps equip you with accurate revenue predictions and helps contain under-utilised surplus.

The Importance of Demand Planning

According to wolterskluwer.com, companies see a 20% curb in inventory spend by implementing a demand planning software strategy. Essentially, engaging the advice of experts helps you plan and forecast accurately.

SME Portal (PTY) LTD helps our clients plan their inventory cycles using both quantitative and qualitative data resources.

Techniques to make your Inventory Management System more effective

These techniques add a dimension to inventory management. Implementing software is easy enough, but best practice demands some practical methods that enhance your initiatives

- KPIs – Creating Goals

Key Performance Indicators (KPIs) are an integral part of every business strategy, including inventory management. They provide a measurable value on how effectively a company is reaching its objectives. Goals should include both monetary expenditures based on value, and make room for product quantities and volumes. Having definitive KPIs in place will help you determine, categorise and prioritise inventories and the management processes best suited to each sector

- Forecasting

Demand planning, as covered above, provides the key to determining how much inventory you need to fulfil orders at any given time. It is crucial to plan re-ordering within the correct timeframe. Re-stocking can only be accomplished with confidence when you have an accurate picture of your stockholding. Software makes the task much simpler and enables you to meet customer needs. It also serves the purpose of aiding you in making predictions based on a reliable information source. Demand planning software will allow you to make adjustments should a particular business scenario change.

- Continuous Replenishment

The JIT (just-in-time) inventory management method requires replenishing stock on a continuous basis as needed, and emulates a pay-as-you-go methodology. Depending on demand, the method concentrates on replenishing low thresholds before stock runs out. The key is determining what ‘low’ means for your business. In order to do that, referring to your inventory quotas will give you a good idea. You should also consider drawing up a replenishment schedule based on data records.

- Keep Up with Quality Control Checks

Routine QA tests will ensure that you maintain quality standards. You want your product to maintain its desirability to your customer, and meet their expectations. Ensure that you aren’t holding onto redundant items. This way, you’ll curb expenditure effectively.

- Implement a Hierarchical System

Identify which items take precedence in the supply chain and ensure that those items are regularly replenished. The FIFO (first-in-first-out) method works well when you’re sending out perishables. Conversely, the LIFO (last-in-first-out) system favours the movement of non-perishable goods. It helps you avoid disrupting an established inventory.

The tier method of importance, or ABC analysis, might suit your needs better. “A” constitutes the most important, and “C”, the least. At the end of the day, choosing the right method depends on your requirements.

- Keep Track of Inventory During Transit

Constant movement can cause confusion. Avoid the error of restricting your inventory checks to your primary location.Make a point of tabulating at all stages of the process.

Whether you plan to automate or manually process your inventory, organisation and optimisation will prepare your business for the future and help you realise your goals.